The Ultimate Guide to Warehouse Wiring: Ensuring Safety and Efficiency

In today’s fast-paced industrial landscape, ensuring that warehouse wiring is both safe and efficient is critical. Poor wiring can lead to safety hazards, increased downtime, and higher operational costs. Whether you’re setting up a new warehouse or upgrading an existing one, understanding the principles of effective warehouse wiring is essential.

Understanding the Basics of Warehouse Wiring

Warehouse wiring involves the installation of electrical systems that power lighting, machinery, and other essential equipment. The wiring must be done according to specific standards and regulations to prevent risks such as electrical fires or equipment malfunctions. Familiarizing yourself with local and national electrical codes is the first step in ensuring compliance and safety.

Key Components of Warehouse Wiring

A well-structured wiring system includes several key components:

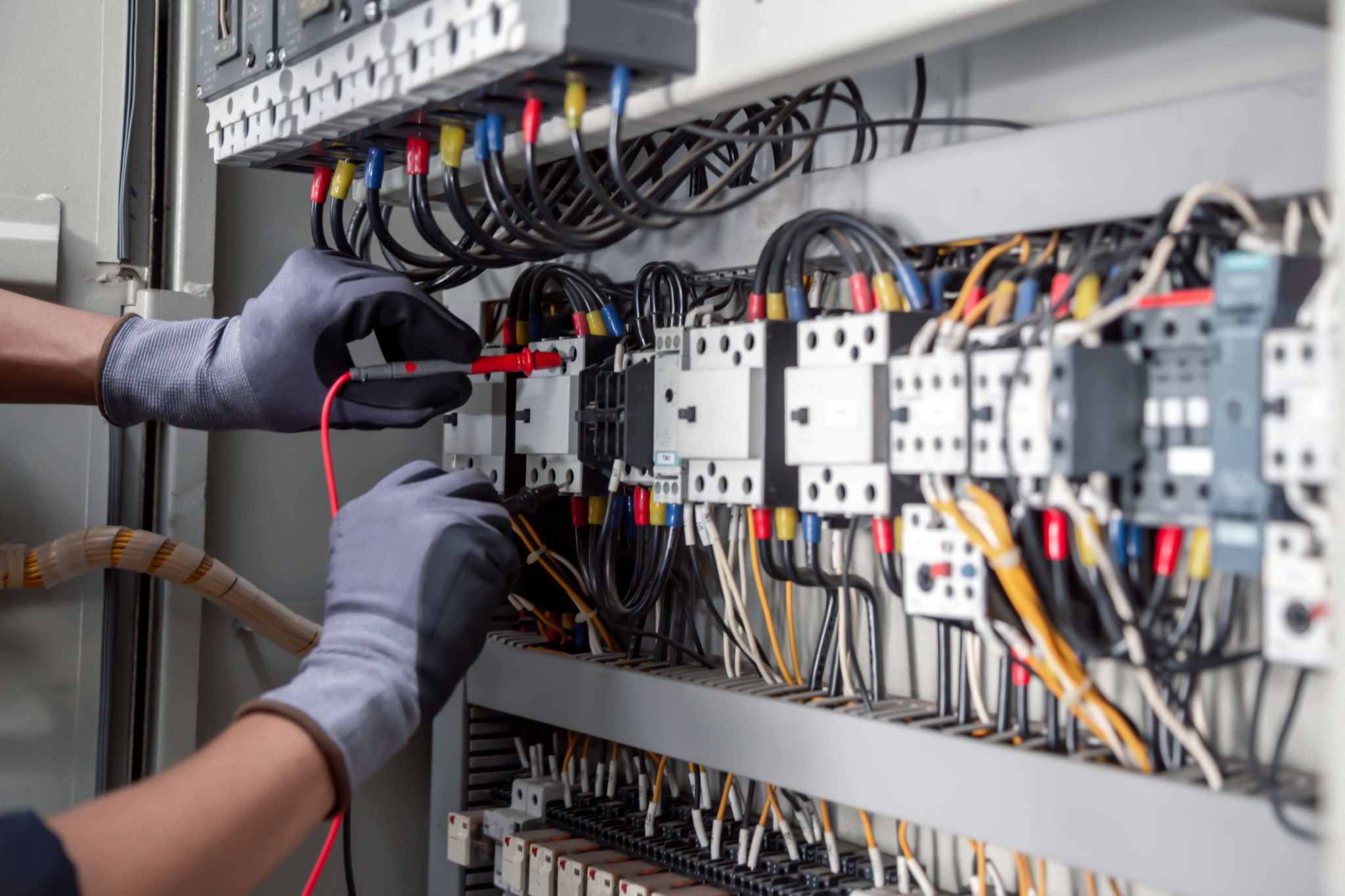

- Circuit Breakers: These devices protect electrical circuits from damage caused by overloads or short circuits.

- Conduit Systems: Conduits protect and route electrical wiring in a building.

- Wiring: High-quality cables are necessary for efficient electricity transmission.

Each of these components plays a vital role in maintaining the overall integrity of the warehouse’s electrical system.

Designing for Efficiency

An efficient wiring system minimizes energy consumption and reduces costs. Begin by assessing your current energy needs and identifying areas where you can improve efficiency. This may involve upgrading to energy-efficient lighting systems or installing advanced control systems that optimize energy use based on occupancy and usage patterns.

Implementing Smart Technology

Integrating smart technology into your warehouse wiring can vastly improve efficiency. Smart systems can monitor energy usage in real time, allowing for proactive adjustments to reduce waste. Additionally, automating lighting and climate control systems can lead to significant savings.

Ensuring Safety Standards

Safety should always be a top priority in warehouse wiring. Regular inspections and maintenance are crucial in identifying potential hazards before they become serious issues. Ensure that all electrical installations are handled by qualified professionals who are familiar with safety standards and best practices.

Conducting Regular Inspections

Routine inspections help in identifying wear and tear or any violations of safety codes. It’s important to establish a regular maintenance schedule that includes checking for exposed wires, testing circuit breakers, and ensuring all fixtures are securely installed.

By taking these steps, you not only safeguard your facility but also enhance its operational efficiency. A well-maintained warehouse wiring system can significantly impact productivity and safety, providing peace of mind for both employees and management.