Case Study: Successful Industrial Electrical Installation by G4 Electric

Overview of the Project

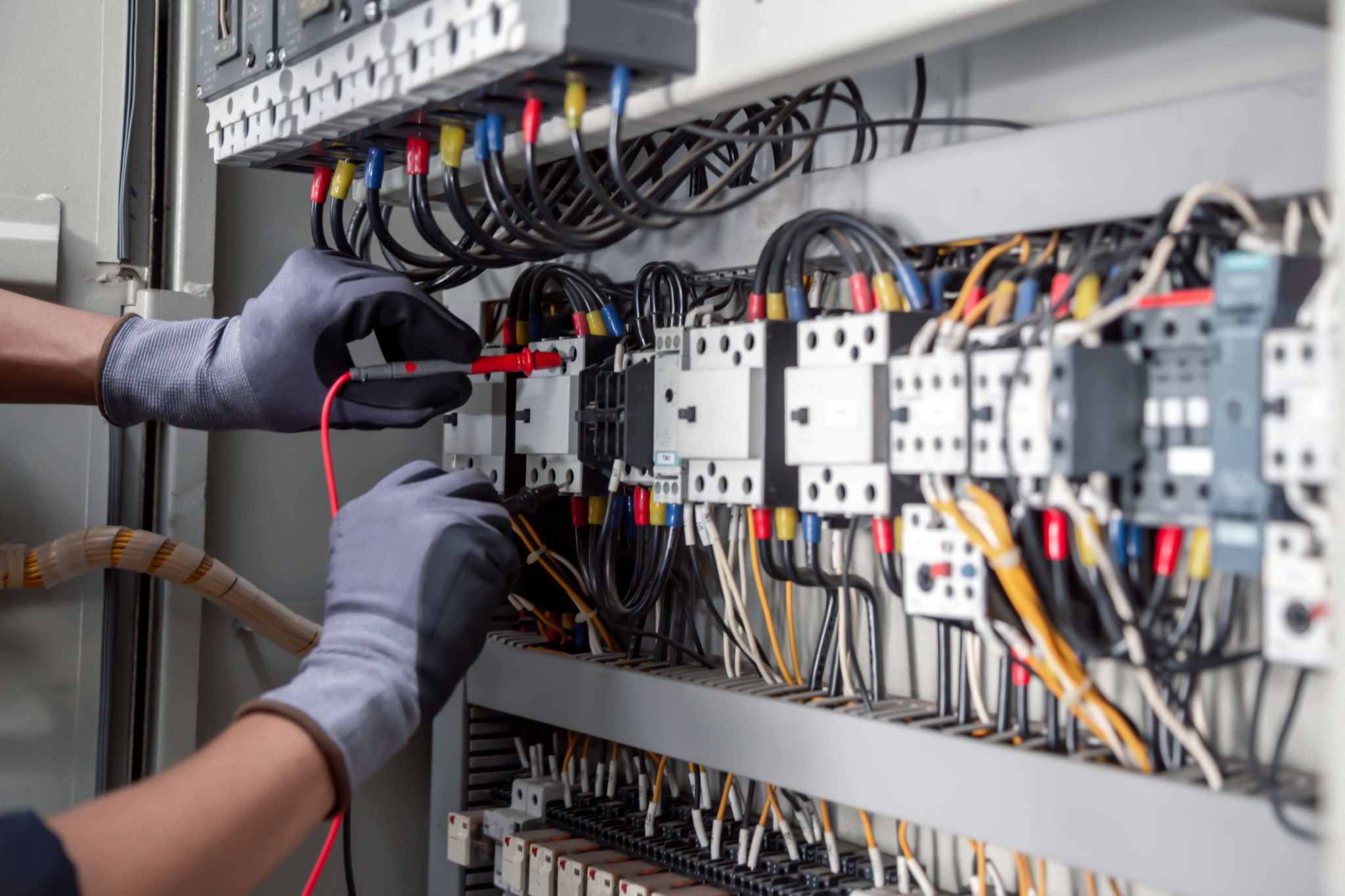

G4 Electric recently completed a notable industrial electrical installation, showcasing their expertise and dedication to excellence. The project involved a large manufacturing facility requiring a comprehensive electrical system upgrade to improve efficiency and safety. This case study delves into the project's challenges, solutions, and outcomes, demonstrating G4 Electric's capability in handling complex industrial tasks.

Initial Challenges

The facility faced several electrical inefficiencies that were causing production delays and safety concerns. Outdated wiring and insufficient power distribution were primary issues that needed immediate attention. The G4 Electric team conducted a thorough assessment to identify all problem areas, ensuring a comprehensive approach to the installation.

Safety Concerns

One of the critical challenges was ensuring the safety of workers during the upgrade process. The facility needed to continue operations, requiring G4 Electric to implement strategies that minimized disruptions and maintained a safe working environment.

Strategic Solutions

G4 Electric devised a strategic plan that included upgrading the electrical infrastructure, installing energy-efficient systems, and ensuring compliance with industry standards. Their team worked closely with the facility's management to schedule installations during off-peak hours, reducing the impact on daily operations.

Innovative Technology

The project incorporated cutting-edge technology to enhance operational efficiency. This included automated control systems and advanced monitoring solutions that provided real-time data, allowing for proactive maintenance and reduced downtime.

Execution and Implementation

The execution phase involved a phased approach to ensure seamless integration with existing systems. G4 Electric's project managers meticulously coordinated with various teams, ensuring that each phase was completed on time and within budget. This systematic execution was crucial in maintaining the facility's productivity levels.

Team Collaboration

Collaboration was a key factor in the project's success. G4 Electric's team worked harmoniously with the facility's engineers and technicians, fostering a cooperative environment that facilitated smooth transitions and problem-solving.

Outcome and Benefits

The completed installation resulted in a range of benefits for the facility. Enhanced electrical efficiency led to reduced energy costs, while improved safety measures significantly decreased the risk of accidents. The facility now operates with increased reliability, ensuring consistent production output.

Client Satisfaction

The client expressed high satisfaction with the project outcomes, praising G4 Electric for their professionalism and expertise. The successful installation has established a long-term partnership, with G4 Electric providing ongoing support and maintenance.

Conclusion

This case study highlights G4 Electric's capability to deliver high-quality industrial electrical installations. Their strategic approach, combined with a commitment to safety and innovation, sets them apart as leaders in the field. As industrial demands continue to evolve, G4 Electric remains dedicated to providing solutions that drive efficiency and safety.